ERL-2000D HIGH SPEED AUTOMATIC LIQUID & PASTE FILLING & PACKAGING MACHINE

FEATURES:

This machine is the compact packaging machine for liquid and paste, which emphasizes its versatility, good performance and easy maintenance. The full-axis servo control manages the data including the pouch size, sealing temperature, filling volume and the timing of each drive axis, and the data of 100 or more products can be stored. The touch panel shows the menu items, such as the "administrative items", "data storage" and "initial settings", which are colored by different usage, and it has perfect performance. Equipped with the film position correcting device, it makes the feeding of various film more stable. The driving section is visible through the clear cover. Each heat roller can be easily maintained from the front or rear of the machine. And more convinient point is the entire cutter device can be taken out by releasing four locks, so that the overhaul can be easily done.

APPLICATION:

This machine is broadly used in packaging liquid soup,cosmetics,cleansing liquid and mayonnaie,which require high filling precision.

SPECIFICATIONS:

|

Filling

Product

|

Liquid &

Paste

|

|

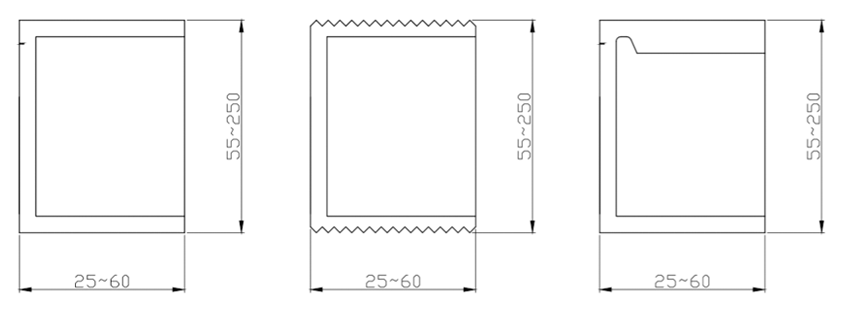

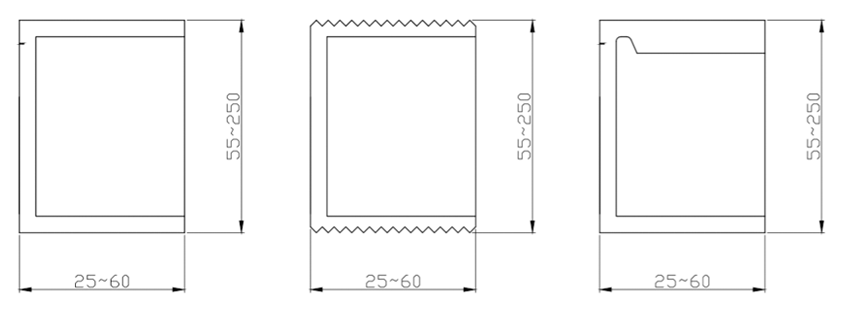

Pouch Pattern

|

3-side seal

|

|

Pouch Height Range

|

2divisions

160-250mm

3divisions 110-165mm

4divisions

80-120mm

6divisions 55-85mm

According to the width of horizontal sealing pouch height range is

different.

|

|

Pouch Width

|

25-60mm

|

|

Packaging Capacity

|

20-300

pouches per minute×2 lane

(depending on pouch height,film composition,product property,etc)

|

|

Filling Capacity

|

1-50ml

(depending on product property and filling device to be used)

|

|

Applicable

Film Width

|

100-240mm

|

|

Maximum Film

Roll Dia

|

¢400mm

|

|

Power

Consumption

|

3-phase 380V 6.5kw

|

|

Air

Consumption

|

|

|

Machine

Dimensions

|

1100mm(L)×1350mm(W)×2100mm(H)

|

|

Machine

Weight

|

Approx.900kg

|

PACKAGING STYLE: